Success Story: Bayer Corporation

| Project Highlights | ||

| Total Project Cost | $4,233,858 |

Bayer incorporated many environmentally beneficial |

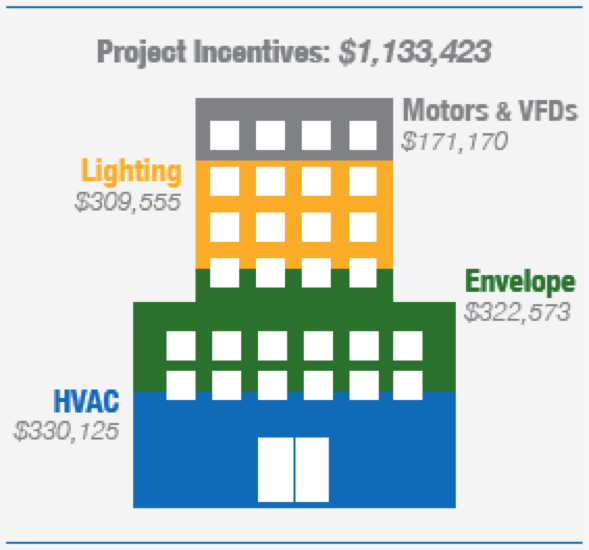

| NJCEP Incentives | $1,133,423 through the Pay for Performance program |

|

| Project Payback | 6 years | |

| Estimated Annual Savings |

4,039,902 kWh |

|

| Pay for Performance Partner |

Energy Squared, LLC | |

|

Technologies LED and fluorescent lighting with occupancy sensors; High-efficiency chillers, direct expansion (DX) cooler, boilers and hot water heaters; Variable frequency drives (VFDs) on pump motors, fans and cooling tower; Low-E windows; Improved insulation |

||

| Project information, savings and environmental benefits were provided by the project contact. | ||

|

Pay for Performance incentives help turn vacant buildings into showcase of energy innovation for construction of new U.S. headquarters Background Bayer has a more than 150-year history developing innovative products and solutions to improve the health of humans, livestock and plants. Seeing the threat that climate change poses to farming and public health, Bayer has undertaken progressively ambitious commitments to lessen the company’s environmental impact. From 2005 to 2013, Bayer reduced greenhouse gas emissions by 18 percent. Bayer has since increased their sustainability targets, with goals of lowering emissions to 20 percent below 2012 levels and improving energy efficiency 10 percent by 2020. In 2010, Bayer operations in the United States were spread across four sites in New Jersey and New York. A decision to consolidate operations became an opportunity to reduce emissions from Bayer facilities through the construction of a more energy-efficient headquarters. A site selection process culminated in 2012 when company officials reached an agreement with New Jersey’s Economic Development Authority (EDA) on tax credits that persuaded Bayer to move into the former Alcatel-Lucent and Bell Laboratories campus in Whippany, NJ, a sprawling 94-acre property in Morris County. With many of the buildings nearly a century old and in need of repair, significant renovation was required to create the energy-efficient headquarters that Bayer had envisioned. Financial assistance from New Jersey’s Clean Energy Program™(NJCEP) provided Bayer with incentives that encouraged company officials to maximize energy-saving opportunities. In turn, the campus’ outdated office buildings became a showcase facility for the latest approaches to energy innovation. |

||

|

When renovating the buildings we came across issues that we did not expect. New Jersey’s Clean Energy Program helped us in our decisionmaking process. Pumps needed to be replaced, for example, and in every case we opted for a more efficient unit. Greg Gullette

Bayer Corporation |

Solution The NJCEP Pay for Performance program Bayer focused their renovation effort on “When renovating the buildings we came Energy conservation measures included Energy Squared, LLC, an NJCEP Pay |

|

NJCEP provided $1,133,423 in performance-based incentives for the $5,367,281 project. According to Energy Squared, the energy-efficiency improvements save Bayer 4,039,902 kWh and 13,530 therms of natural gas per year, resulting in annual energy cost savings of $526,876. The energy-efficiency features are expected to pay for themselves in about eight years. After construction was completed in 2013, Bayer pursued Leadership in Energy Design (LEED) certification from the U.S. Green Building Council. Incorporating more energy-efficient features into the construction process allowed Bayer to surpass initial expectations and receive Platinum designation, the highest level of LEED certification. |

|

More Information

.jpg)